The Ken Rosewall Arena Description

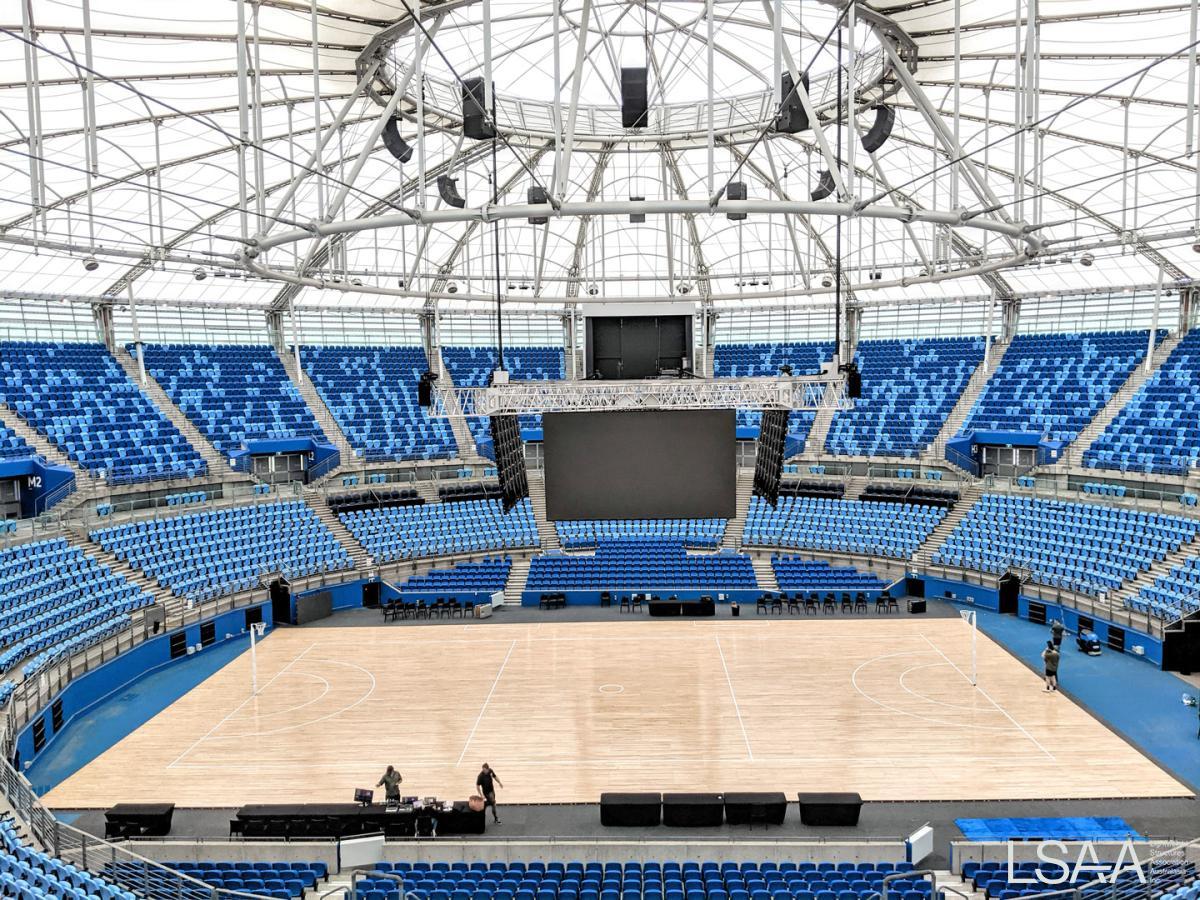

The Ken Rosewall Arena project is a redevelopment project for the original stadium which was constructed in 2000 for the Sydney Olympic Games. The project included the installation of an innovative cable-tension and PTFE fabric design roof. The striking new roof is the first of its kind for stadia in Australia. The redevelopment has transformed the venue into a multi-purpose outdoor covered arena with new and upgraded facilities. The arena now operates as a multi-purpose venue, including tennis and netball, and is home to the Sydney Giants.

DESIGN / FABRICATION / INSTALLATION BRIEF

The Ken Rosewall Arena redevelopment project aimed to transform the existing tennis arena from an open-air venue into a multi-purpose indoor arena. The idea behind the roof was to allow the venue to operate unaffected by environmental impacts such as extreme heat, wind, and rain. The client requested a solution that could transform the venue into a multi-purpose outdoor covered arena with upsized in-stadia videoboards, new seating, and shade for 10,000 spectators.

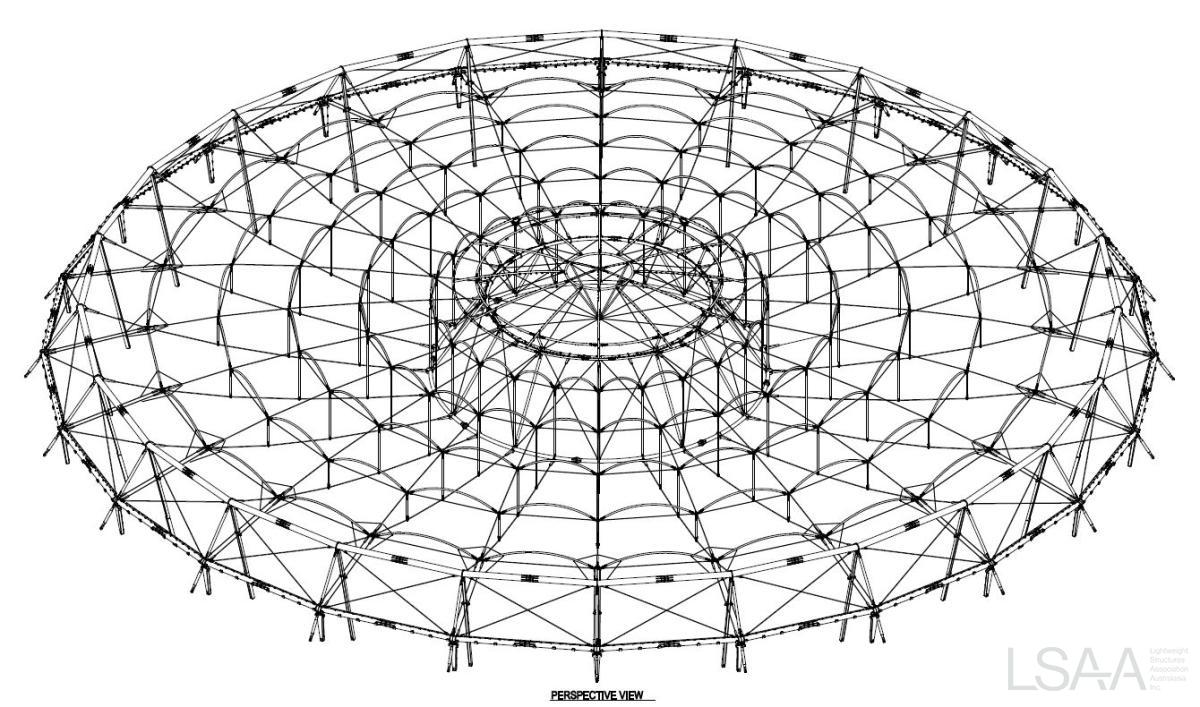

Fabritecture was contracted for the design, supply, fabrication, and installation of a striking new compression ring style roof clad with PTFE coated fiberglass fabric over the existing bowl. The roof comprises of a complex combination of hoops, struts, cables, and steel, clad with high strength PTFE coated fiberglass. This particular roof design was selected as a very efficient way to cover a round area.

STRUCTURAL SYSTEMS

The symmetrical cable net system was engineered to suspend 91 tonnes of steel between supports. This system enclosed the roof to create the indoor arena. The tension cable system of the structure suspends the centre popup roof by spanning between steel tension rings and compression rings.

Above the central, hovering tension ring is the ‘popup roof’ which boasts 360-degree operable louvres to allow natural ventilation of the stadium whilst also remaining weatherproof during events. The suspended roof span between supports is 92 meters.

Compression rings are part of the main concrete plats arounds the stadium and were installed on opposite sides to evenly load the pre-existing structure

MATERIALS

FGT-800 PTFE coated fiberglass by Chukoh was selected to clad the roof due to its high tensile strength, high durability (35+ year design life), low maintenance (due to low friction coefficient meaning it self-cleans with the action of rain), and non-combustible fiberglass substrate.

At night, the translucent fabric glows when the internal arena lights are on. The PTFE fabric was installed from work platform nets and rope access allowing simultaneous redevelopment of the stands and court below.

FABRICATION

The fabric panels were patterned with installation time frame in mind. This allowed rapid tensioning of the fabric over the cable bay arches.

To guarantee symmetry of the new steel structure, the tension and compression rings were designed and fabricated using steel shim plates between the major steel connections.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

The arena had a tight turnaround between construction and opening events during the Christmas-New Year period. The ATP Cup was the first event hosted at the newly redeveloped arena which was a hugely successful event. The design and construction of this project was extremely efficient, with less than 12 months between beginning formal design at the start of the year and completion by Christmas.

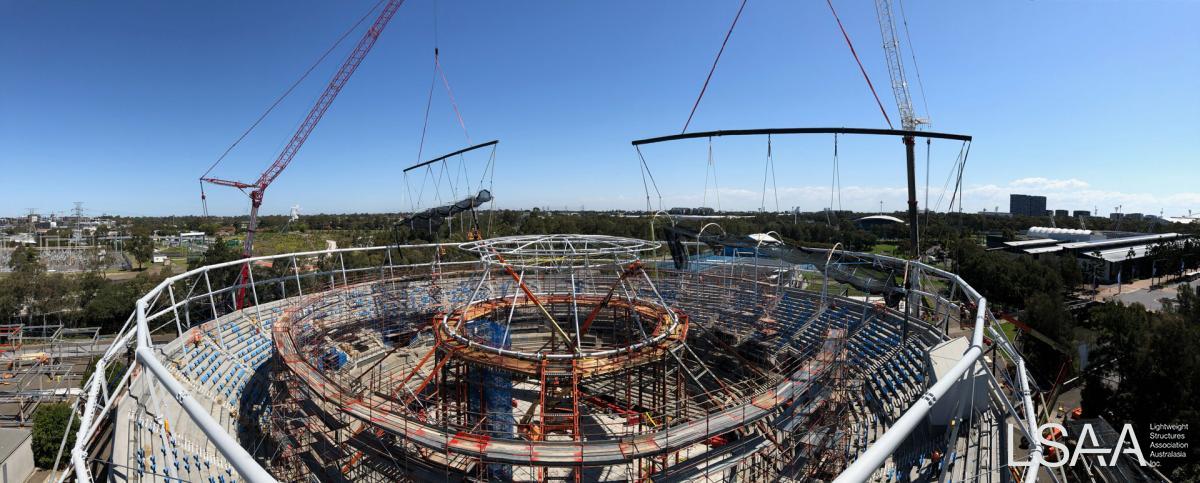

The tension ring at the centre of the roof is made of steel, not cable. This is not typical of a cable net roofing system and required tight install force control during cable tensioning to protect the integrity of the steel tension ring. The arena roof needed to be tensioned systematically so as not to introduce damaging loads into the supporting concrete plats. This was achieved by symmetric tensioning of the cable net.

We developed a unique installation method utilising temporary support tower to reduce the ‘big lift’. Preassembly on the ground made installation faster and reduced the temporary engineering requirements. This in turn improved the safety conditions on site. The Client also benefited from a significantly reduced programme. The final results of the arena were fantastic, and the client was extremely pleased.

COSTS

The Ken Rosewall Arena project was valued at AUD$12.3m.

COLOUR IMAGES

Filename Caption and Credits

4009_01 Aerial shot of Ken Rosewall Arena (photo credit: Ethan Rohloff)

4009_02 Interior shot of Ken Rosewall Arena (photo credit: COX Architecture)

4009_03 Aerial shot of Ken Rosewall Arena (photo credit: Ethan Rohloff)

4009_04 Interior shot of Ken Rosewall Arena

4009_05 Interior shot of Ken Rosewall Arena

4009_06 Interior shot of PTFE fabric (prior to bleaching)

4009_07 Aerial shot of Ken Rosewall Arena (photo credit: Ethan Rohloff)

4009_08 Installation shot of Ken Rosewall Arena

4009_09 Aerial shot of Ken Rosewall Arena (photo credit: AW Edwards)

4009_10 Installation shot of Ken Rosewall Arena

4009_11 Installation shot of Ken Rosewall Arena

4009_12 Installation shot of Ken Rosewall Arena

4009_13 Installation shot of Ken Rosewall Arena

PROJECT CREDITS

Project Name: Ken Rosewall Arena

Location: 2 Rod Laver Drive, Sydney, NSW 2127

GPS Location: -33.85401852066214, 151.07189468874876

Completion Date: 20/12/2019

Preferred Category (1-8): 4 – Large Structures > 1,000m2

Entrant Name: Fabritecture

Address: Unit 14/15 John Duncan Court, Varsity Lakes, QLD 4227

Telephone Landline: +61 7 5587 7000

Mobile: +61 408 402 716

Email Address:

Website Address: www.fabritecture.com

Entrant Type / Role: Designer / Installer

Project Client: Tennis NSW

Project Architect: COX Architecture

Structural Engineer: ARUP Group; Maffeis Engineering

Building Contractor: A W Edwards

Fabricator(S): Confidential