This project was entered in the LSAA 2016 Design Awards (Cat 2, Medium Fabric Structures 1293)

Entrant: Shade And Membrane Structures Australia (Design / Project Management / Install)

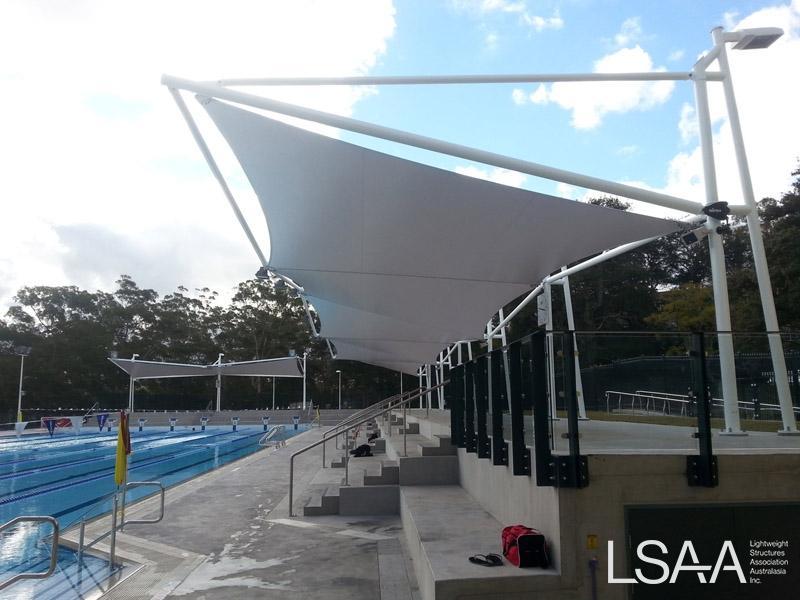

Location: Hornsby, NSW. Completed: April 30 2014

Client: ADCO Constructions / Hornsby City Council

Team: Peter Hunt Architects, Larry Shyu Global Membrane Design, ADCO Constructions, Shadecom / Fabric Solutions

Application: To design, engineer, fabricate and install approximately 400 sqm of waterproof shade structures to cover two seating areas.

Description:

Working closely with the council, their architects, the builders and the engineers for over 18 months we were able to come up with a design that suited both the architectural and practical intent. With the centre opening in July 2014, the council are extremely pleased with the outcome. We were basically asked to cover the seating areas of two sides of the pool to provide both cover and international water polo standard lighting to the pool area.

Structural System

The overall cantilevered Hypar design was developed as a collaboration between Shade and Membrane Structures Australia and our preferred engineer - Larry Shyu of Global Membrane Designs - and was finally signed off by the council after about 8 months of design and revision work.

Materials

Ferrari 802s was selected for the fabric. Stainless steel cables and connections along with Triplex painted steel and membrane plate were used to ensure long life and extended periods of non-maintenance.

Fabrication

We contracted out both the steel and membrane fabrication. Patterning was done by Larry Shyu of GMD which was sent to Fabric Solutions for nesting, plotting and welding using their high frequency welders

Collaboration

We developed strong relationships with all teams in the design and supply chains. We provided extended warranty and carried out regular maintenance inspections.

Ref: sliders/DA2016/Cat2/1293 DP ID 108