The project was entered in the 2013 LSAA Design Awards (Large Structures, #3301)

Entrant: Global Fabric Structures (UFS)

Location: Sydney

Client: Thiess Australia

Completion Date: December 2012

PROJECT DESCRIPTION:

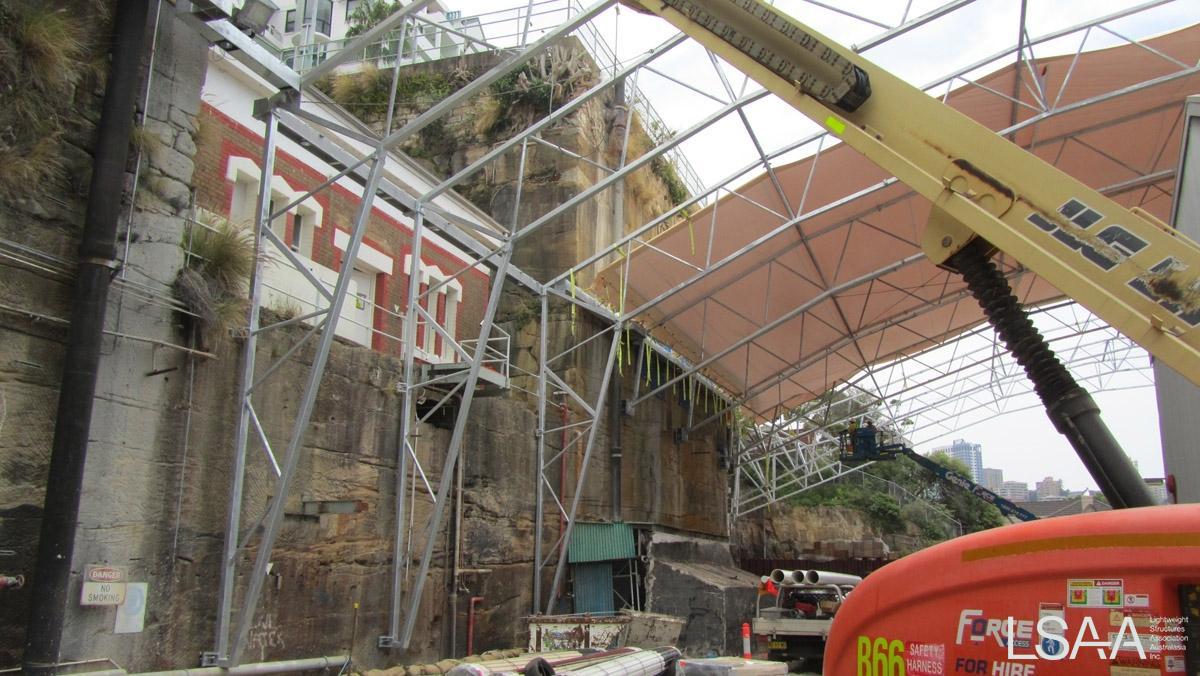

The former HMAS Platypus site is nestled below the suburb of Neutral Bay, Sydney Australia on a quiet harbour inlet.

This site has been an integral part of the history of Sydney Harbour since the early 1800's. A gasworks, a workshop for servicing torpedoes and a base for Australian Submarines have a left a contaminated industrial site that is excavated out of sandstone and spread over several levels.

The site has an area of approximately 1.8 hectares and includes 11 buildings and structures, some of which are of heritage significance. The soils, bedrock and groundwater on the site are contaminated, predominately related to the former gas works operations.

The Sydney Harbour Federation Trust acquired HMAS Platypus in 2005 and has commenced the restoration, for the enjoyment of present and future generations to enjoy the history, heritage and harbourside location.

The fabric structure needed to cover the entire Northern Section of the HMAS Platypus site. Within this northern region the contaminate soil will be excavated and treated by adding cement and GAC in a TMSR. The stabilised product will be reinstated in the northern section of the excavation.

The types of activities that are likely to occur with the fabric structure generate dust, odour and volatile organic compounds emission in the building environment. In addition to that the exhaust fumes from mobile plant such as excavators, trucks and the TMSR will contain particulates, NOx, CO and diesel mists.

The Platypus Remediation Enclosure needed to perform the following functions:

-

Enclose the entire northern section of the site

-

Control fugitive emissions of dust, odour and VOC emissions generated from the remediation activities, from escaping to the outside

-

Prevent storm water from the northern section and surrounding catchments from entering the works

-

Limit the visual and noise exposure of the remediation operation inside the structure

-

It needed to be a clear span structure and could not have any columns or obstructions as part of the supporting structure within the footprint of the remediation area.

-

The Fabric Structure must be airtight

-

The fabric must be a sandbank colour or similar

MATERIALS

Nova Shield II with ArmourKote

Galvanised Steel

FABRICATION

The HMAS Platypus Remediation enclosure was unique challenging and complex as attention to the historical nature of the site and its iconic place in the City of Sydney's journey was paramount.

This was the largest construction to date of our Supa-Span S Product, customized specifically for this project, a combination of steel framing, fabric paneling and a unique proprietary tensioning system.

The location of this installation, with access being limited, not only for transportation and site but also the consideration of the environmental impact of our installation on the surrounding community.

The use of multiple cranes, located not only on site, but all from the above cliff tops to assist with installation.

From an engineering perspective, the customization of our largest fabric structure, to allow for the protection of heritage listed items, including drain pipes on the cliff face and buildings dating back to the 1870's, remaining with the footprint of the fabric structure, ensured that this project was unique.

The Fabric Remediation Enclosure was completed in December 2012.

An airtight remediation enclosure designed, engineered and installed which following the end of remedial works in late December 2013 will be decontaminated, removed and recycled/redeployed ensuring a completely holistic approach has been adopted.

Credits:

•Structural Engineer: Wade Design Engineers

•Fabricator: Global Fabric Structures

•Installer: Global Fabric Structures