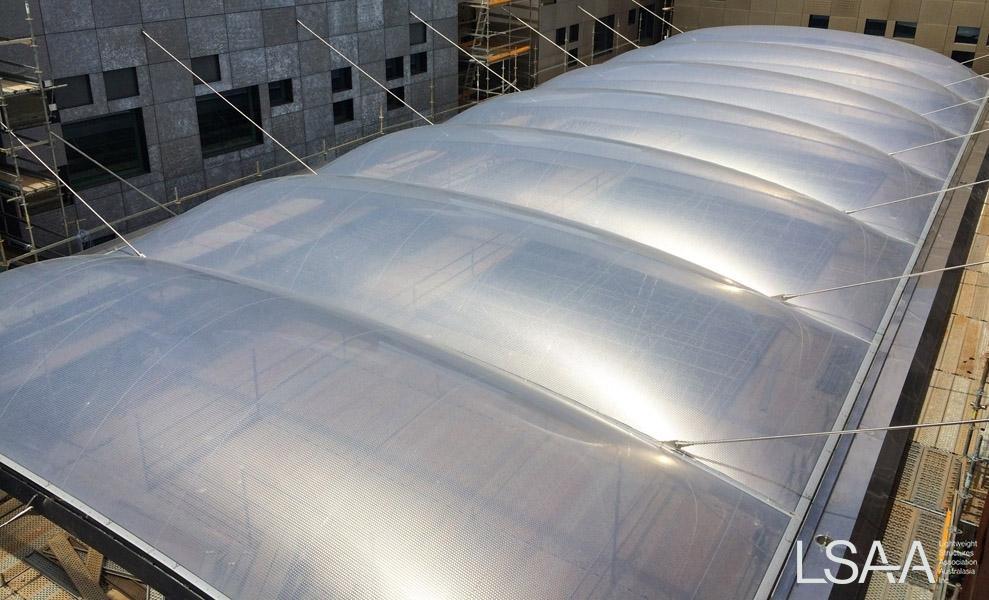

Jakarta ETFE Canopy

Entrant: Fabritecture (Designer and Installer)

Location: Jakarta, Indonesia. Completed: June 2015 Client: Leightons Asia

Team: Denton Corker Marshall, Maffeis Engineering, Fabritecture, Seele Covertex

Application: ‘Floating’ canopy suspended over a courtyard using a 2-layer ETFE cushion system, supported exclusively by stainless steel tie rods

This project was entered in the LSAA 2016 Design Awards (Medium Fabric Structures, 8128)

Description

The Jakarta Embassy is Australia’s largest embassy complex in the world, providing commercial office space for Australian and Indonesian staff, residential facilities for Australian officers and a range of recreational spaces.

The ETFE project was designed as a floating canopy over the Chancery courtyard area to keep people sheltered from the elements. The structure was specifically manufactured for longevity, utilising 316 grade stainless structural steel & ETFE foil.

The project is located in Jakarta, Indonesia, within the Australian Embassy

Design Brief

The purpose of the project was to provide shelter over the courtyard of the Chancery building. The canopy was designed to ‘float’ within the space, supported by stainless steel tie rods that are fixed to the concrete substructure of the main chancellery buildings to create the aesthetic illusion.

The design required a canopy that offered complete protection from the elements to the courtyard area below. The specification for the design also required longevity from the structure, hence the use of stainless structural steel and long lasting ETFE.

Structural Systems

The project had parameters that we don’t get to work with often, which provided some occasional challenges. The use of 316 grade stainless structural steel was the most complex element of this project, as the material can be very challenging to work with. A 100% trial assembly in the factory was completed prior to installation as stainless steel is extremely difficult to modify. This meant no holes or drilling could occur on site, so everything had to be perfect before it arrived on site. Tolerances of ETFE are tight, so the Structural stainless steel framing system had to be perfect.

The installation required working within a courtyard therefore the space didn’t allow for any access equipment. The entire installation was by scaffold, which had to be built up to the 10th storey. A tower crane was used to drop the frame components into place from above.

Project-specific challenges experienced during installation included language barriers, working with local contractors, customs issues with delivery of materials and equipment.

The ETFE canopy is unique, not only because of the combination of stainless structural steel & ETFE material, but also the suspension of the entire structure via tie rods to ‘float’ in the courtyard.

Materials

The structural stainless steel support frame was chosen primarily for the longevity of steel, as well as its architectural capabilities.

ETFE was the chosen fabric because it is lightweight, highly translucent, and conforms to the design concept of a floating ‘cloud’-shaped canopy. ETFE: the ETFE foil was fabricated using standard industry techniques.

Collaboration, Construction and Maintenance

Collaboration with wall plates behind the cladding was necessary prior to the wall plates being installed. The plenum and ducting system is disguised, coming from the main building towards the canopy, and within the structural system of the canopy.

Costs and Conclusions

The total value of the project is AUD$819,000

The completed project took 1,210 man hours to complete, and has produced an exceptional result. The ETFE canopy resembles a floating cloud above the Chancery courtyard, providing an aesthetic protective solution for the outdoor area. This project met the brief & design expectations. The structure performs the function it was intended, reflecting a successful project. The innovative design of the ETFE canopy has created a space that allows the courtyard to have plants, but remain protected from the outside world.

{Ref} sliders/DA2016/Cat8/8128 DP ID 109