Structural Design of the Arch and Roof of Wembley Stadium

Kourosh Kayvani, PhD, FIEAust, CPEng

Aurecon, Sydney, Australia

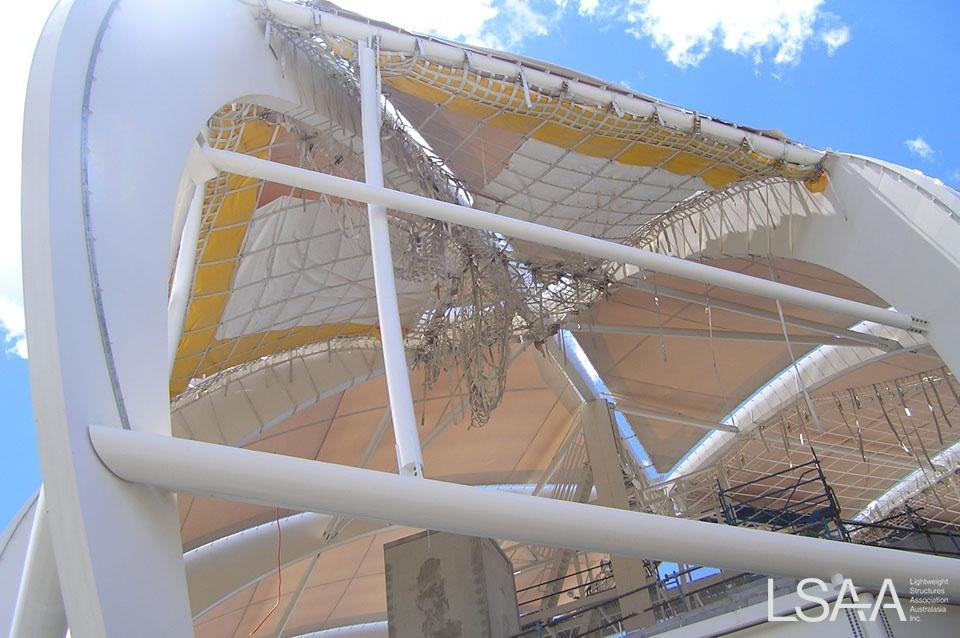

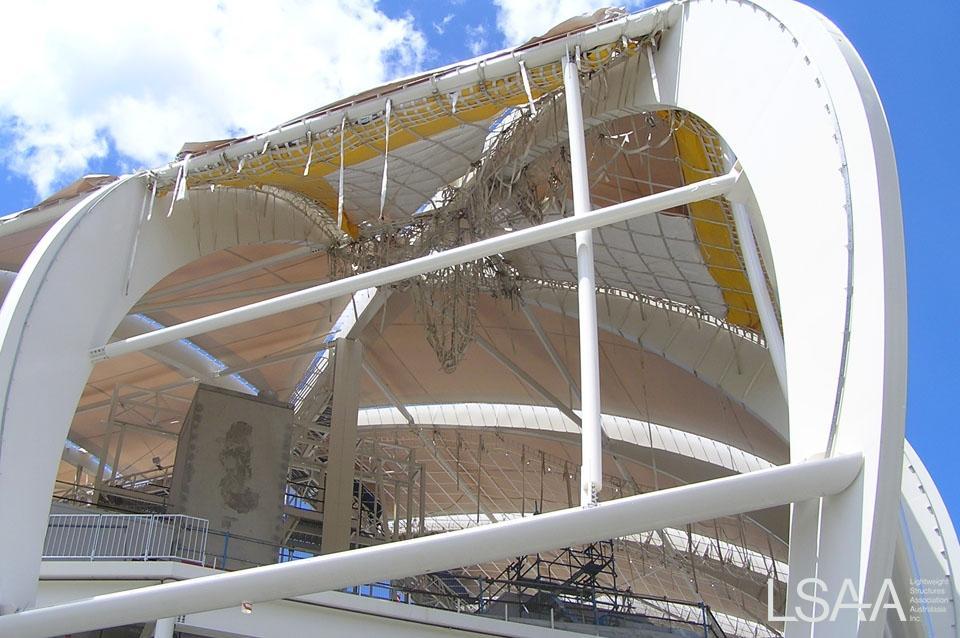

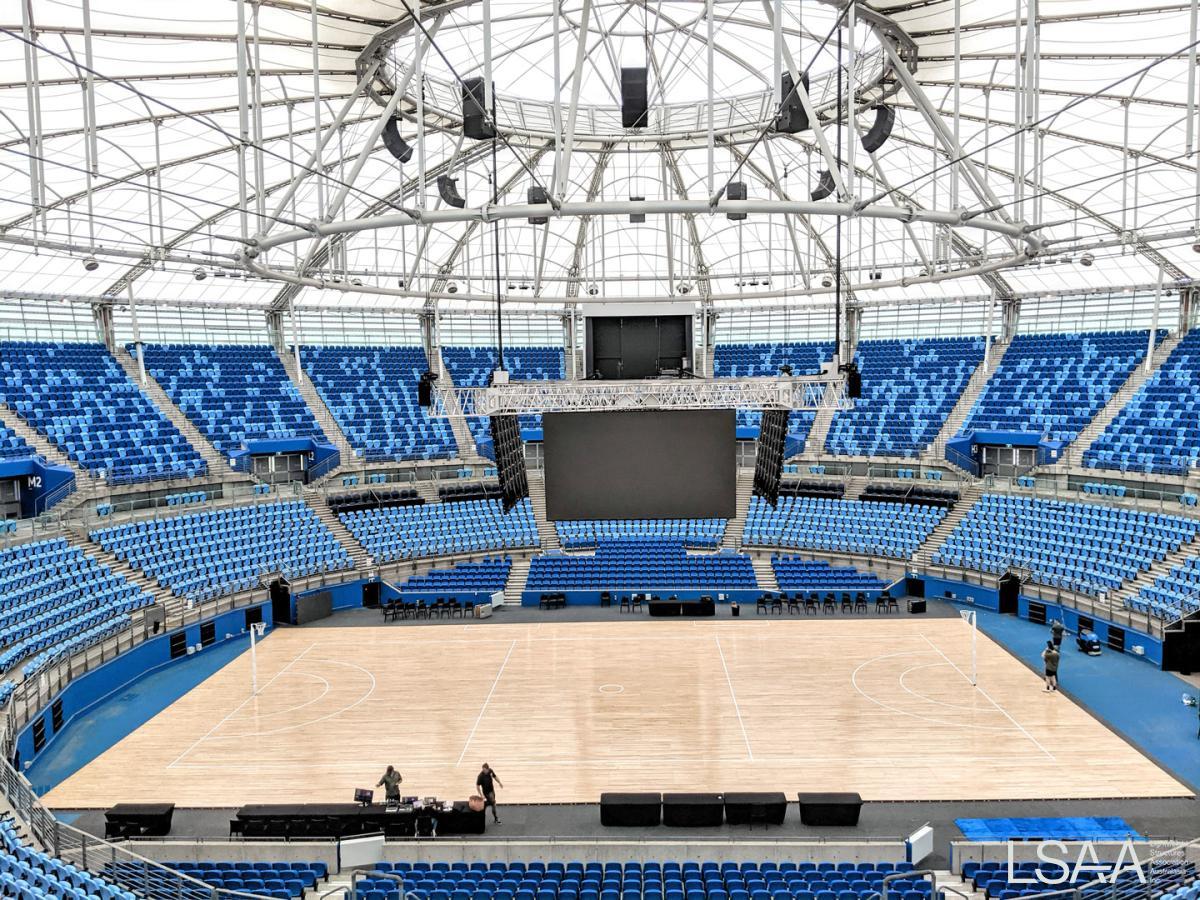

ROOF DESCRIPTION

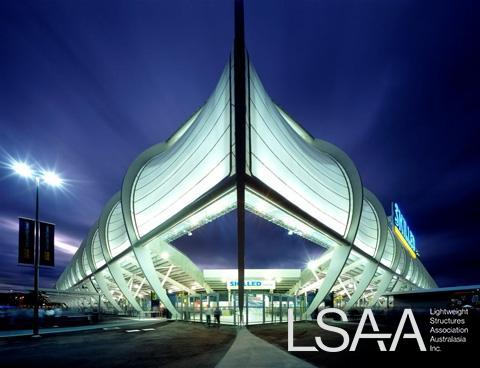

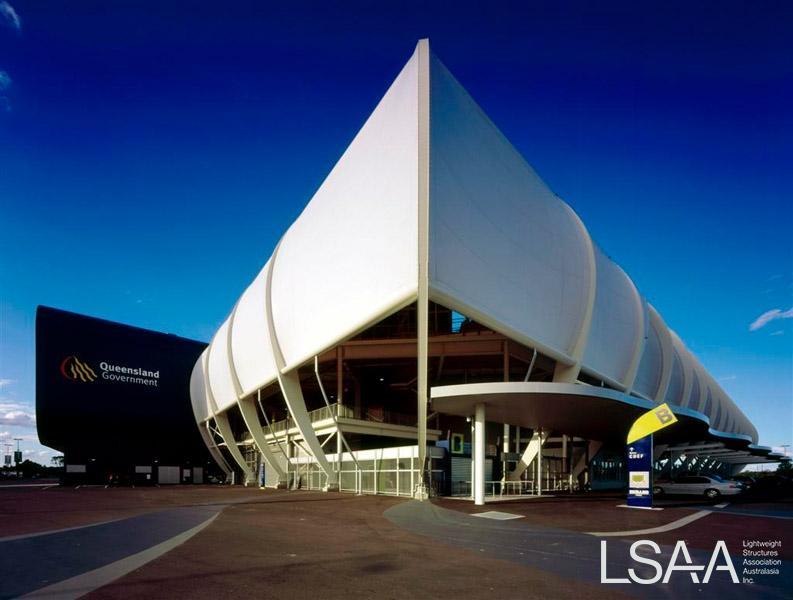

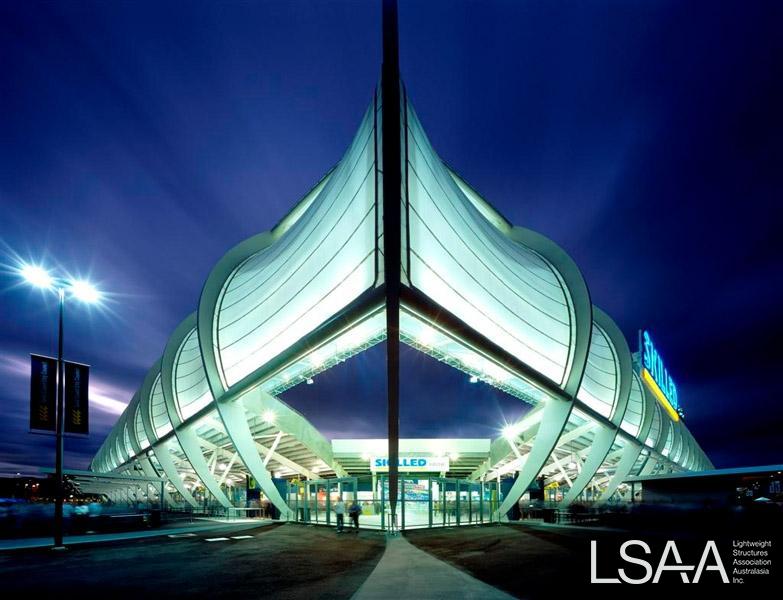

The aim of the new Wembley Stadium was to design and build a state-of-the-art national stadium, unlike any other in the world. The new stadium, with its elegant exposed steel structure arch, is an international icon as was the old stadium with its twin towers which was built in 1923.

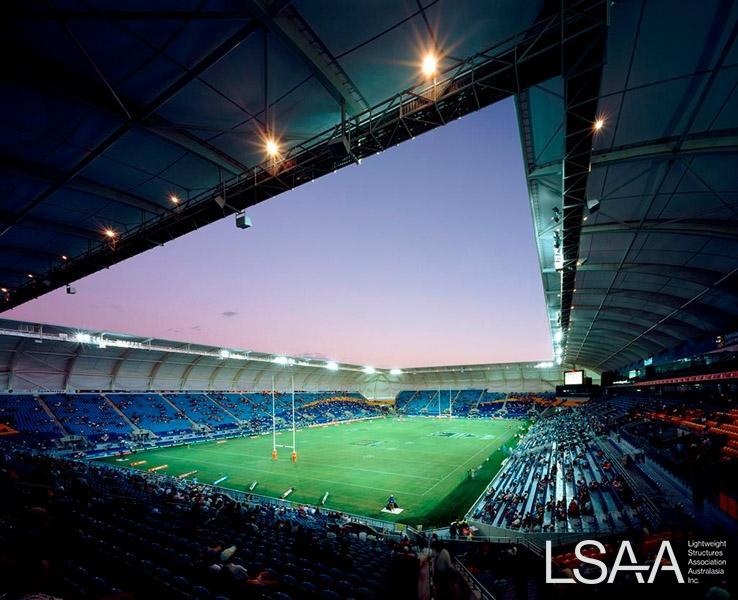

The design brief required the roof not to cover the playing field which lead to one unique aspect of the roof in that it partially retracts over the seats to allow the daylight to reach all points of the pitch and thus a shadow-free playing field.

The retractable roof is formed by seven separate independently driven roof panels totalling 15,000 sqm that move in a parallel motion to the south as they "open" and stack on the top of one another when in a fully "open" position.

With the retracting roof panels all moving to the south, the roof design exploits the opportunity to have a tall, structurally efficient structure on the north side to support the north and south roofs. The solution was to have an elegant and structurally efficient arch which spans the entire width of the stadium's seating bowl (Figure 1).

Email for complete paper.