2024 LSAA Design Awards Entry - #5000 Narre Warren Metro Station- Cable Truss Ceiling Support

IDENTIFICATION NUMBER 5000

ENTRY CATEGORY (1-6) 5

ENTRANT ROLE Specialist D&C Subcontractor

PROJECT NAME: Narre Warren Metro Station- Cable Truss Ceiling Support

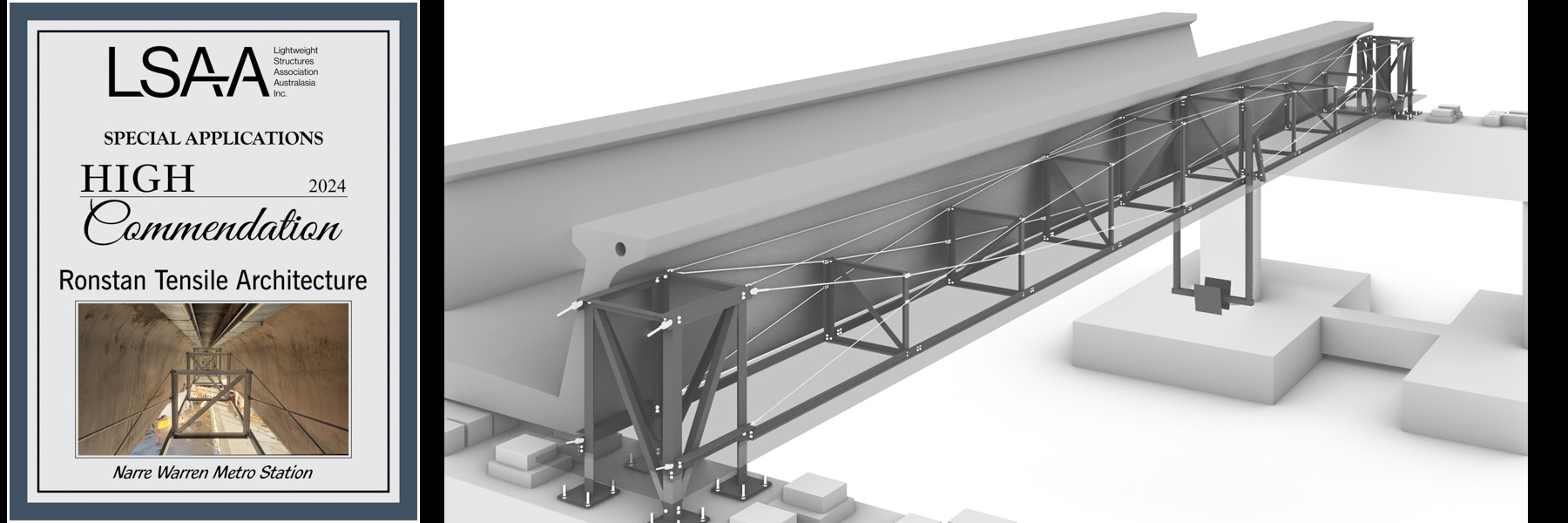

APPLICATION OF PROJECT: Cable Bow truss and secondary framing supporting ceiling and PID screen.

PROJECT DESCRIPTION:

How 3 Tons of Steel & Cable Replaced 30 Tons of Structural Steel: A New Era in Sustainable Infrastructure

On March 28th, 2024, the newly reconstructed metro stop at Narre Warren station, a critical junction on Melbourne’s Pakenham Line, was officially opened to the public. This station, one of the busiest along the line, had long been plagued by a hazardous and congested rail-road crossing. The recent rebuild of Narre Warren Station, now elevated above the streets in a sleek skyline crossing, is a significant achievement in the city’s ambitious Level Crossing Removal initiative.

The redesign of Narre Warren Station not only addresses the critical safety and congestion issues but also introduces a groundbreaking structural innovation that sets a new benchmark for urban infrastructure projects. Originally, the station's ceiling was to be supported by pairs of 800mm deep welded Universal Beams, each spanning 25 meters between substantial crossheads.

The initial design, however, presented significant challenges: the sheer weight of the structural steel—amounting to 30 tons—would not only complicate installation but would also necessitate a complete halt to rail services during the construction process.

In response to these challenges, Built Environs sought an innovative solution from Ronstan Tensile Architecture. Collaborating closely with Tensys Engineers, they developed a pioneering cable truss system that dramatically reduced the required structural steel. This new design, utilizing just 3 tons of tensioned Ronstan ACS2 cables and bespoke galvanized steel elements, effectively replaced the cumbersome 30 tons of conventional structural steel. The cable truss system, comprising four precision-engineered stainless-steel cables arranged in a parallel crossing pattern, supports the station’s ceiling with minimal material use.

The benefits of this lightweight cable truss solution extend far beyond its immediate structural advantages. The reduced weight of materials translates directly into energy savings during both the manufacturing and transportation phases, significantly lowering the project’s carbon footprint. Additionally, the modular nature of the cable system allows for incremental installation without disrupting rail operations, a critical consideration for a busy metro line. The ease with which this system can be dismantled also offers future flexibility, allowing for straightforward modifications or deconstruction as urban needs evolve.

Moreover, the environmental impact of the project is considerably mitigated. By reducing the need for 27 tons of steel, the resource dependency is dramatically lowered, conserving natural resources and reducing greenhouse gas emissions associated with steel production. This sustainable approach not only enhances the environmental credentials of the Narre Warren station but also sets a precedent for future infrastructure projects within Melbourne and beyond.

As the first implementation of its kind, the structural cable system at Narre Warren station is a trailblazer, showcasing the potential for similar applications in upcoming projects. With several more stops along the Pakenham Line yet to be elevated, this project underscores a critical shift towards more sustainable, resource-efficient, and environmentally friendly construction practices in urban infrastructure development.

While very different from mainstream tensile structures more often demonstrating aesthetic free flowing form, this highly functional structure confirms to the definition as a lightweight structure in that it achieves its long span and low self-weight through the intelligent utilization of high strength cables/materials which have been designed through an optimization process to efficiently service the critical load cases – a multidisciplinary effort coordinated by the specialist contractor with the engineer, architect and other stakeholders.

The success at Narre Warren is a promising indicator of the broader adoption of such innovative solutions, paving the way for a more sustainable future in metropolitan transit systems.

DESIGN / FABRICATION / INSTALLATION BRIEF

Built Environs approached Ronstan to assist with the development of an alternative lightweight cable truss support structure as an alternative to the heavy 800WB’s spanning 25m between cross heads to support a ceiling over the station entry concourse.

Ronstan developed the design concept and engaged Tensys Engineers to undertake the detailed design. Ronstan was then responsible for shop detailing, fabrication and installation of the cable trusses, ceiling support framing and PID support framing.

Stilcon assisted Ronstan with steel fabrication and installation.

Metro Trains project requirements for an alternative design are complex and tortuous.

STRUCTURAL SYSTEMS

Pair of stainless-steel cable bow trusses in each of 3 bays supporting secondary steel framing that provides direct support for panelized ceiling structure above.

Bow trusses sit in the narrow space above crossheads between precast track support beams.

No direct support from the track support beams is permitted.

The cable trusses replace the original design – 3 pairs of 800 WB’s spanning 25m between cross heads.

We replaced 30 T of structural steel with 3 T of bow truss and secondary framing.

MATERIALS

Ronstan ACS2 1x19 S/St G316 Cables in 8mm, 10mm and 14mm diameter selected for the cable behavior and load capacity. All cable end fittings had fully articulated toggle/fork pin connections allowing for polymer bushes for corrosion protection and isolating dissimilar metals.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

The project involved 4 levels of design certification, independent reviews and very close collaboration and coordination between Ronstan and builder, Built Environs to get the alternative design approve. Everything was questioned and comprehensive responses had to be prepared to satisfy the Metro Trains scrutiny.

Construction methodology was developed by Ronstan with the cable system installed with the correct design tensions using secondary tensioning devices in accordance with the requirements.

Maintenance. Careful consideration was given to materiality. All steelwork had to be hot dip galvanized after fabrication and Ronstan Grade 316 cable and fittings were utilized and isolated carefully at the connection points to maximize life and minimize maintenance.

COSTS

The Ronstan solution brought about substantial cost savings for the client that are commercial in confidence.

One of the key benefits is that should the ceiling ever need to be removed during a renovation the complete structure can be simply dismantled and removed in a process much simpler than removing 25m long steel beams each weighing 6 tonnes.

COLOUR IMAGES