Project Title: Singapore Bird Paradise

Media Release Statement

In an interview conducted shortly before his passing, Frei Otto, one of the heroes of tensile architecture and engineering, spoke of the Munich Zoo Aviary as his “best art building, architectural building”, a space where the same landscape transcended the thin-wire boundaries: where, in a structure that disappears against a blue sky, less truly is more.

Project Title Trinity Point Tension Membrane Structure

Media Release Statement

This structure is good example of meticulous collaboration and process detail.

All steps were covered in the completion of this unique and detailed structure with complex scope.

The result of all this work was a spectacular vibrant structure, that created beautiful natural light during the day, and a flamboyant illuminated ambience at night time.

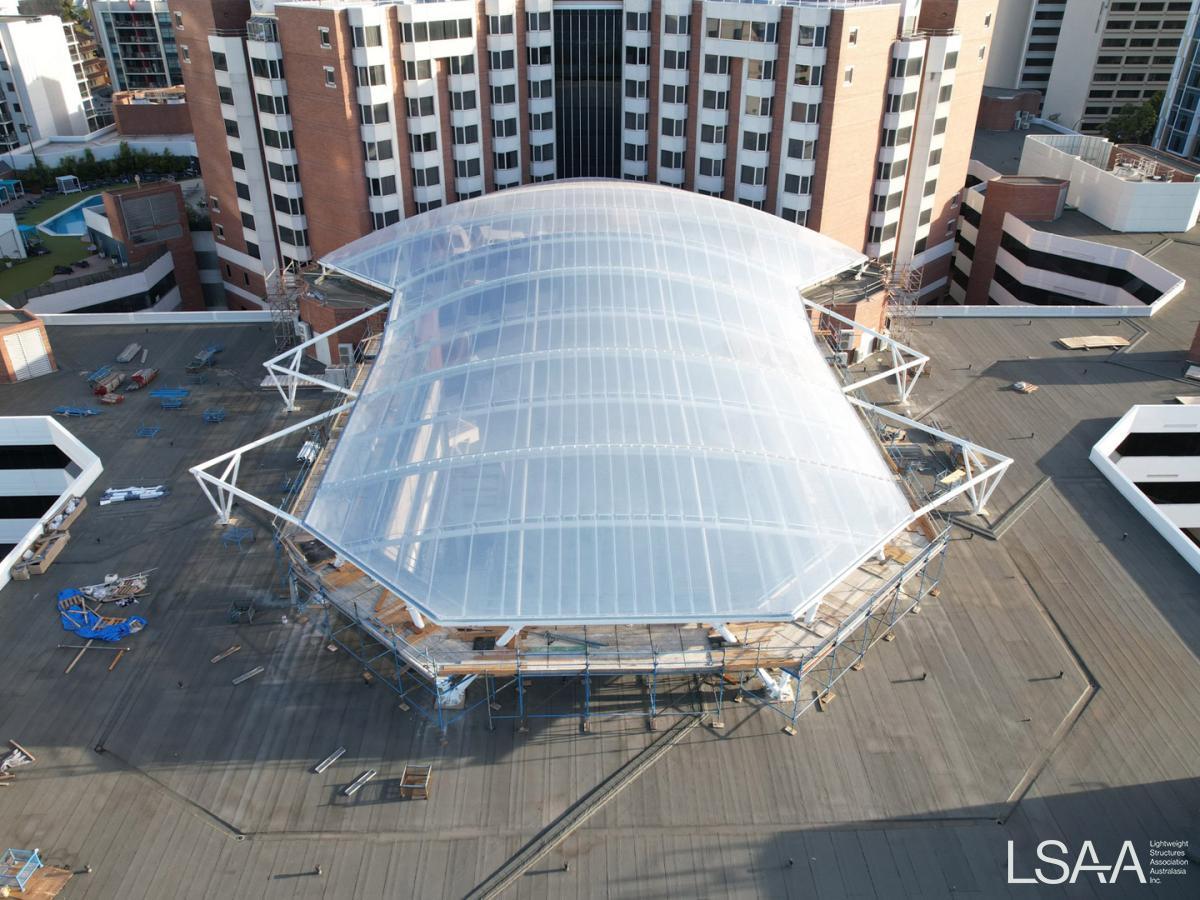

Project Title: Link@Langley ETFE Atrium

Caption: The Link@Langley ETFE Atrium - photograph by Skyskills Industries Pty. Ltd.”

Media Release Statement

Nestled along the picturesque Perth riverside, this custom-designed, 1665m2 single-layer ETFE canopy crowns the central atrium of a revitalised shopping, dining, and entertainment district, transforming the former Fortescue Metals HQ into a contemporary urban hub.

The architectural vision for the Atrium was clear in both intent and design. The goal was to create a visually striking, yet functional glazed feature skylight element that enhances the appeal of the riverside redevelopment.

Project Title: Sydney Football Stadium Roof

Caption: the Sydney Football Stadium roof, completed in late 2022 is set to become an iconic example of lightweight structural design.

Sydney Football Stadium Roof: An iconic example of lightweight structural design.

The Sydney Football Stadium Roof project stands as a monumental achievement in architectural innovation and lightweight structural engineering, redefining stadium design in Australia. This remarkable project, executed in collaboration with the NSW government, along with some of Australia’s leading project architects, engineers, construction firms, exemplifies the extraordinary potential of tensile membrane structures.

The design of the stadium creates a cohesive architectural language that integrates the Stadium Domain, Seating Bowl, Façade, and Roof.

Project Title: Whitten Oval

Caption: The impressive new indoor training facility at Whitten Oval with its unique lightweight tensile membrane roof. Photo by Grant Kennedy.

Revolutionary Whitten Oval Indoor Training Facility Roof Sets New Standards in Lightweight Structural Design

The Western Bulldogs AFL Football Club's historic Whitten Oval precinct has been transformed with the addition of a revolutionary 50m x 35m multi-purpose indoor training facility featuring a translucent tensile membrane roof. This project, a standout in Australia, exemplifies cutting-edge innovation in lightweight structural design.

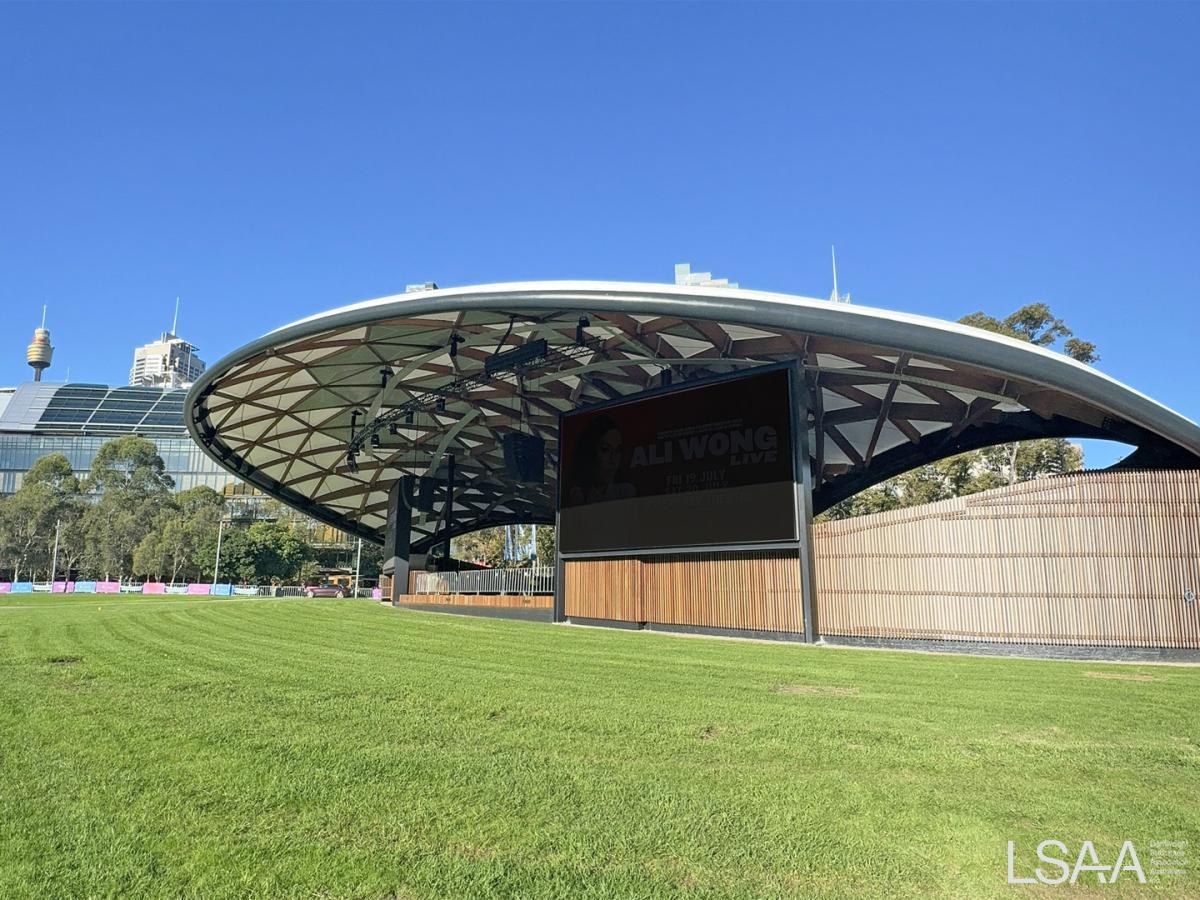

Project Title Tumbalong Green Amphitheatre Roof

Caption: The Tumbalong Green Amphitheatre in Darling Harbour – photo by MakMax Australia.

Stunning Shell-Shaped Amphitheatre Roof Unveiled at Darling Harbour

The Tumbalong Green Amphitheatre in Darling Harbour now boasts a striking new architectural landmark – a shell-shaped roof designed to captivate audiences and elevate performances. The newly completed amphitheatre roof blends cutting-edge design with engineering excellence, marking a significant upgrade from the previous bat-wing style tensile membrane stage roof.

Project Title Wangun Amphitheatre

Caption: Smoking ceremony at the Wangun Amphitheatre – photo by Rory Gardiner

Media Release Statement

The Wangun Amphitheatre, commissioned by the Gunaikurnai Land and Waters Aboriginal Corporation (GLaWAC) was conceived as a vibrant cultural hub, and stands as a testament to the harmonious blend of traditional heritage and modern lightweight structure design.

Located in the heart of Gunaikurnai country, the Wangun Amphitheatre’s design is deeply rooted in cultural symbolism, featuring five elliptical tensile membrane canopies representing the five Gunaikurnai clan shields.

Project Title: North Melbourne Primary School Circle Shade

Caption: The bright orange shade structure at North Melbourne Primary School – photo by John Gollings

Bright Colourful Circle Shade Structures at North Melbourne Primary School Set New Standards in Lightweight Shade Structure Design

The North Melbourne Primary School's new vertical campus features a groundbreaking addition that redefines conventional school shade: three circular shade structures positioned at different levels, made possible through innovative lightweight structure design and engineering. This project highlights the school's commitment to creative outdoor spaces within a limited area, blending functionality with aesthetic appeal.

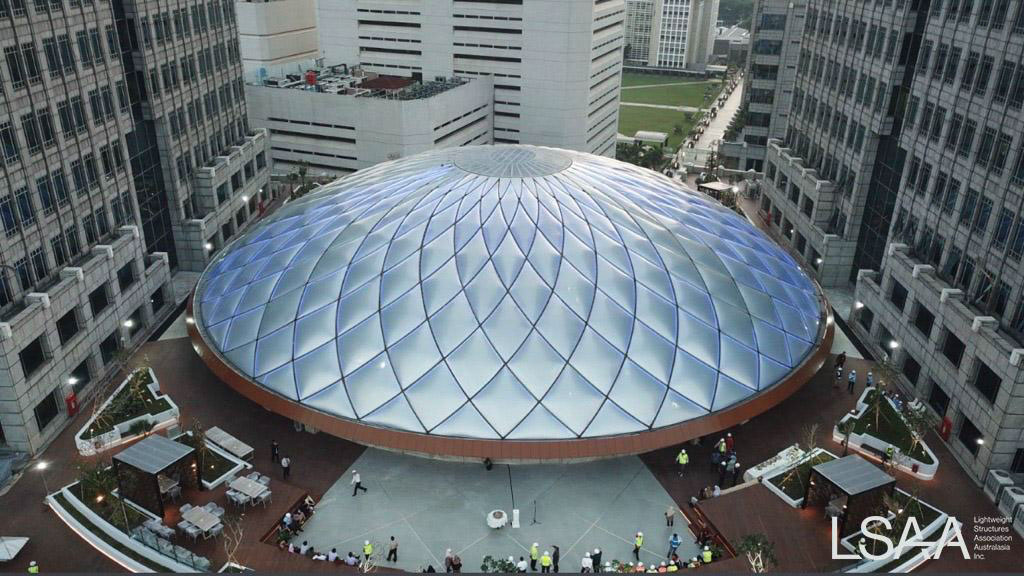

Project Title Bank of Indonesia Millennial Function Hall

Hero Image - Aerial Shot of Bank of Indonesia Millennial Function Hall

Media Release Statement

The Bank of Indonesia Millennial Function Hall is a groundbreaking architectural achievement that features a striking 53-meter diameter ETFE dome. This innovative structure, encompassing 2,700 square meters and constructed from 325 ETFE cushions, exemplifies both aesthetic sophistication and advanced engineering.

The dome's design integrates a custom ETFE (Ethylene Tetrafluoroethylene) roof system

Project Title National Throws Centre of Excellence Canopy

Exterior shot of National Throws Centre of Excellence Canopy (Angus Martin Photography)

Media Release Statement

The throws run-up canopy at the Queensland Sports and Athletics Centre (QSAC) is an innovative structure, designed to enhance the State Athletics Facility, and provides a world-class environment for athletes specialising in discus and hammer throwing.

The design brief required a canopy that would offer athletes a safe, comfortable, and weather-resistant training space.

Project Title The Bower Tree Precinct Facade

Exterior shot of The Bower Tree Façade (Lucy RC Photography)

The Bower Tree Dining Precinct Facade

This Bower Tree dining precinct in Sippy Downs exemplifies the essence of lightweight structures, celebrating its transformative design and construction of the striking aluminium façade screens, showcasing Fabritecture's expertise in marrying aesthetic innovation with functional excellence.

Engaged to create a unique façade screen,

Project Title - Field of Dreams, Oxford Falls

Exterior Shot of Field of Dreams, Oxford Falls (Paramount Studios)

Media Release Statement: Oxford Falls Grammar School’s “Field of Dreams”

Oxford Falls Grammar School’s “Field of Dreams” project exemplifies a harmonious blend of functionality and aesthetics, addressing both the practical needs of weather protection and the visual integration with the school's architecture.

The bespoke canopy, commissioned for two competition basketball courts on the upper level of a two-story building, features a PTFE tensioned fabric roof structure renowned for its durability and weather resistance.

Project Title MSU John Goodman Amphitheatre

Exterior shot of MSU John Goodman Amphitheatre (Photo credit: Gayle Babcock, Architectural Imageworks LLC)

Media Release Statement

Missouri State University’s (MSU) innovative John Goodman Amphitheatre epitomises the fusion of cutting-edge design and environmental resilience, positioning itself as a premier destination for a diverse array of performances and events.

The John Goodman Amphitheatre was conceived to accommodate a wide range of activities, from concerts and theatre to lectures and cultural events. Faced with the challenge of creating a versatile space that could withstand varying outdoor conditions such as rain, wind, and sun exposure, the design team rose to the occasion.

Media Release Statement

Fabric Structures Limited is proud to announce the successful completion of our innovative acoustic ceiling panel solution at the Metro Sports Facility. As a leader in designing and installing bespoke tensile fabric structures, we were tasked with delivering a custom solution that combines advanced acoustic performance with a visually striking design.

The Metro Sports Facility, a premier venue in Christchurch,

“The Te Hiku Sports Hub in Kaitaia is an integral addition to the community, fulfilling the need for a multi-purpose sports facility that caters for the young, old, and everyone in between.”

Media Release Statement The Te Hiku Sports Hub in Kaitaia

In April 2023, Fabric Structures Limited was proud to announce the completion of the Te Hiku Sports Hub in Kaitaia, a landmark project that showcases cutting-edge design and engineering excellence. This state-of-the-art facility is now a central hub for community sports and activities in the Far North region.

The Te Hiku Sports Hub, designed with a focus on modern functionality and aesthetic appeal, features bespoke tensile fabric structures that seamlessly integrate with conventional insulated wall cladding systems.

Fabric Structures was proud to announce the successful completion of the re-roofing project for the West Grandstand at Yarrow Stadium, Taranaki in March 2023. This landmark project not only enhances the structural integrity of the stadium but also integrates modern design elements that reflect the cultural heritage and community spirit of Taranaki.

Project Title Hamilton Workingman’s Club Canopy

Hero Image 3214_08 “Complete installation of the partial bowling green enclosure at Hamitlon Workingman’s Club.”

Fabric Structures Limited was pleased to complete the successful installation of a canopy enclosure at the Hamilton Workingman’s Club, marking a significant enhancement to the venue’s outdoor space.

The project, which began with a comprehensive design and engineering phase,

Media Release Statement: Kina building at Green School New Zealand

Fabric Structures was proud to see the successful completion of the fabric roof membrane for the Kina building at Green School New Zealand. This landmark project exemplifies our commitment to advanced engineering and sustainable building practices.

The Kina building, a cornerstone of Green School NZ’s innovative campus, features a striking fabric roof

Fabric Structures was proud to announce the successful design, fabrication, and installation of a new hall canopy at Matakana School, located in the picturesque region of Matakana, New Zealand. This project highlights our commitment to creating functional, aesthetically pleasing, and durable fabric structures tailored to meet the specific needs of our clients.