APPLICATION OF PROJECT:

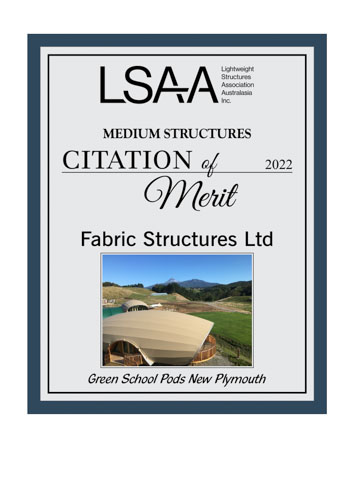

3 Pod like classrooms at Green School NZ

PROJECT DESCRIPTION:

To provide an outer skin from a material that can be recycled if/when replaced and also blends into environment. Wastage of non-recyclable materials to be kept to a minimum.

Also to provide the support frame to take the PVC membrane.

DESIGN / FABRICATION / INSTALLATION BRIEF

It was requested by the architect that we would supply a membrane solution for three-pod like classrooms for Green School New Zealand, to function as an aesthetic cladding and to create a ventilated thermal barrier to reduce a “heat soak effect” into the building. This was to complement the “green” label for the structure, reducing running costs and adding an organic look.

STRUCTURAL SYSTEMS

The overall complexity of the project was caused by the intriguing shape and challenging geometry, also the construction materials which were proposed.

The glulam timber beams implicated large tolerances on site, which required the steel components to be customized to match each of the three structures.

3d- digitizing of the design assisted by the construction of the tension-membranes. The high stretch of the fabric paired with the shape of the structures added the additional complexity of staged tensioning over multiple weeks.

MATERIALS

Mehler – Valmex Lodge de lux FR – 580gsm PVC

FABRICATION

The fabrication had complex geometry as the fabric had a high weft compensation which meant minimum tolerance to allow for the correct fit. The geometry for the fabric started with digital site measure using a Proliner first, followed by computer controlled cutting many checks and keder length dimensions to ensure accurate final panel size.

A similar process was used for the steel fabrication given the challenging geometry.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

Being a bespoke membrane structure Cleland Construction Limited had to overcome the different approach from standard construction methodology and Fabric Structures & Cleland Construction work well to get the desired effect. This was mainly around a realization that fabrication off a 3D model was not going to create a successful outcome, therefore a proliner measure once the steel had been installed, then fabrication (with multiple QA check s) was agreed.

COSTS

Design – 12% Fabric – 6% Fabrication – 6% Steel – 50% Extrusion etc – 4% Installation – 22%