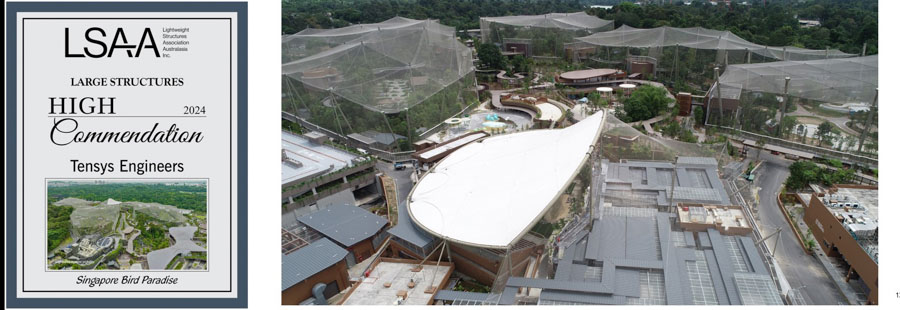

2024 LSAA Design Awards Entry - Singapore Bird Paradise

IDENTIFICATION NUMBER PE 0625

ENTRY CATEGORY (1-8) ALTERNATE CATEGORY (1-8)

PROJECT SIZE 5 Aviaries and 1 amphitheare (100,000 sqm) + 3,000 sqm

ENTRANT ROLE Designer/Engineer

Project and Application: Singapore Bird Paradise

In 2016, it was announced that Jurong Bird Park will be moved to a larger park at Mandai Lake Road. This move was part to consolidate the park with 3 other wildlife parks and a new Rainforest Park creating the Mandai Wildlife Reservice. The new Park Bird Paradise was opened in May 8 2023

DESIGN / FABRICATION / INSTALLATION BRIEF

The project was to create a series of avairies using a cable net and stainless steel mesh that will not only house the wildife and conservation purposes but also provide a unique environment whereby patrons can traverse within the habitat (along elevated walkways) and learn about the wildlife (within various pods) and be at one with nature (at the tree tops)

The aviaries were required to cover over existing trees.

Aviaries are

- Tropical Velley & Songs of the Forest

- Dry Forest & Jewel of the Forest 1 & 2

- Jewel of the Forest 3,4,5

- Crimson Wetland

Flight path of the birds (within the enclosure) required a more rectangular enclosed space which further makes it difficult to create a doubly curved form.

The site has to include not only the aviaries but also the back of house (BOH) and administrative buildings. The overall planning created a very confined space to develop mast + tieback solutions. In some instances, we had to resort to tripod columns.

Tensys approach the project with iterative forms to create a low curvature roof structure and balance the overall forces of the structure such that the close proximity of the inclined columns and tie backs resulted in elements that were visually elegant.

The forms had to also hug into the existing ground. This meant working with the existing undulated terrain to create the perimeter boundaries and location of columns and tieback supports. This added to the complexity of finding a balance of forces and form for each of these aviaries.

STRUCTURAL SYSTEMS

Each aviary is unique in its form and created to suit both terrain, trees and requirement of paths and roadways and buildings.

The many constraints made it difficult to create the form.

The structural form embarked on was using a series of internal columns with ridge cables to the boundary perimeter mast and tieback columns. At the same time, stabilising cables above the columns were introduced to ensure that construction of the cable net and columns can be carried out and free standing whilst indvidual mesh panels are installed.

On the amphitheatre, Tensys worked with RSP to create a pringle shape form. However due to the constraints of the perimeter, there was low curvature towards the rear end of the amphitheatre roof. Inverted conics were built into these zones to help funnel the tropical rainstorm.

On the Crimson Wetland structure, there was a free span requirement of 100m x 30m height. This was created using a combination of ridge and suspension stay cables for the structural system

MATERIALS

The choice of material and the layering effect can be attributed to the study of light and shading thru 3 layers of material

Amphitheatre – PTFE/Glass fabric

Cable net – galfan strand and lockcoil cables

Mesh - stainless steel ferruled mesh

The client’s requirement to have a 25 year maintenance free period also meant there was close study of the paint system, corrosion protection regime and inspection regime – post construction.

FABRICATION

Describe the fabrication techniques and equipment used, including special methods employed and level of tolerances required:

Cables were manufactured in Germany by Pfeifer and required to have sockets ends (with no adjustment) This added more complexity to ensuring that the foundations and steelwork will fit.

The stainless steel mesh was manufactured by in Vietnam (under supervision from Swiss supervisors and management)

COLLABORATION, CONSTRUCTION AND MAINTENANCE

A team effort of collaboration between all parties on the project, (from end client project managers), Obayashi (builder) and specialist contractor (Pfeifer), steel fabricator (TTJ) during the planning of construction to ensure the fit of all components.

The project stretched thru Covid and was challenging in having to make countless trips to Singapore (quarantining) for meetings and inspections to keep the projects going. Throughout the period, all parties collaborated and provided support to each other – from the construction worker to end clients.

COSTS

Give details of the costs involved in the design, fabrication and construction of the project (if known and non-confidential). Alternatively some percentage indication of effort spent in conceptual design, detailed design, fabrication, material cost, erection and completion costs:

The whole project for Obayashi was SGD750,000. The specialist work on the aviaries and amphitheatre, it was SGD 35,000,000.

COLOUR IMAGES