APPLICATION OF PROJECT:

Upgrade of Bridge Fall Protection.

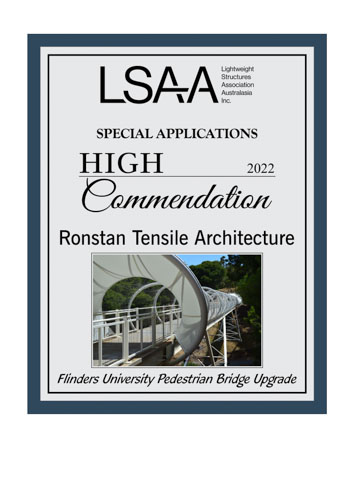

X-Tend Mesh tunnel along bridge with non-climbable PTFE/Glass fabric collars at bridge abutments.

PROJECT DESCRIPTION:

The pedestrian bridge was originally constructed in 1964 (when Melbourne last won its penultimate premiership) with structural steel frame and bondek style (composite) concrete slab deck. It is more than 100m long.

The structure links the student halls of residence with the main teaching campus and crosses a deep ravine between the two sites. The route provides the most direct access between the two. Prior to being decommissioned for a period of time due to safety, forcing students to face either a challenging walk down through the darkened ravine at night or a lengthy bus ride, the bridge route had been one of the university’s more highly trafficked walkways.

The design team was approached to investigate and recommend between the demolition and construction of a new compliant bridge, or undertaking extensive landscaping works to create a safe alternate route through or around the ravine.

At first the upgrade of the existing bridge had not been considered feasible, but with new materials and meshes it was felt the university could upgrade the bridge making necessary maintenance repairs at the same time as improving bridge safety for users.

Ronstan was approached to help Cox investigate ways of introducing a mesh barrier solution that would meet today’s safety standards, while adding only minimal structure due to capacity limitations of the existing bridge design.

The solution was achieved by constructing a lightweight tunnel of X-Tend tensile stainless steel mesh supported by new steel arches. Tensioned fabric collars were designed and installed on larger steel arches providing non-climbable barriers at both abutments. The existing bridge upgrade was not only found to be the most cost effective and sustainable solution, but it saved a historical university landmark, enhancing the structure and experience for users with new lighting features.

DESIGN / FABRICATION / INSTALLATION BRIEF

Cox Architecture developed a concept entailing the construction of a fully enclosed lightweight tensile mesh tunnel along the length of the bridge. A fabric collar was constructed at each end of the bridge that would provide no footholds and would prevent access to the outside of the mesh tunnel.

The solution needed to be lightweight and highly permeable to the wind as it needed to work within the existing capacity of the then 55 year old bridge structure.

Ronstan was consulted during the design process and the concept was further developed and simplified to make it easier to construct and to better suit the characteristics of the chosen Carl Stahl X-Tend mesh.

X-Tend mesh is highly porous to wind and was deemed to be the most appropriate cladding. It has excellent structural properties, good durability and is highly transparent. Ronstan was engaged by Built to undertake the detailed structural design of the additional steel structures required to support the mesh and fabric with Mott Macdonald checking the capacity of the existing structure.

The capacity of the existing bridge also fed into the installation methodology. As part of the bridge rectification works a lightweight gantry was suspended from the bridge deck eating into its residual capacity for the mesh barrier works.

Ronstan designed and constructed a lightweight derrick that was manually maneuvered across the bridge capable of lifting the prefabricated and finished steelwork arches from the unloading bays at either end of the bridge and rolling them into position on the bridge.

STRUCTURAL SYSTEMS

The structures are composed of prefabricated and finished steel arches attached to the bridge decks by bolting through the existing bridge deck.

Offsite finishes ensured high quality and durable finishes.

Bolts holes in the deck were grouted with epoxy after install to ensure there were no adverse effects on durability of existing concrete.

Steel arches were held in place and braced with Ronstan Cables which became part of the permanent structure.

The X-Tend mesh surface formed a complex saddle surface profile so the mesh panels were patterned in Aus and then fabricated as rectangular panels by Carl Stahl in Germany. This ensures panels could be installed at site to fit the surface without adjustment.

Similarly, the fabric panels making up the funnels at each end of the bridges were also patterned in Aus. and fabricated in Sharjah by Hardco before being shipped and installed on site to fit the pre-planned surface without adjustment.

Fabric panels wrapped around the inclined steel rings at the bridge entries.

MATERIALS

Carl Stahl stainless steel X-Tend mesh D2mm wire nominally 100mm x 173mm diamond shaped aperture.

This material was selected due to its versatility, strength, durability and high porosity to wind.

Verseidag B18089 PTFE coated glass weave fabric.

This material was adopted for its excellent fire performance, strength, durability and availability. It was in-stock at Hardco.

FABRICATION

No special methods employed.

The novel aspect was patterning of X-Tend to make complex saddle surface from a fabricated rectangular mesh panel by allowing diamond aperture sizes to vary across the surface.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

There was close collaboration with the Project Design team to ensure that all stakeholders were satisfied with the planned works.

Once we had an accurate 3D scan of the bridge structure we had a solid base for developing our as-built forms.

Close collaboration with Built was required to ensure our works were coordinated with other remedial works on the bridge being undertaken by others at the same time.

PROJECT CREDITS

Project ID Number 2082

Project Name Flinders University Pedestrian Bridge Upgrade

Project Location Ring Road, Bedford Park

City / Suburb AdelaideState SA 5082

Completion Date Sep-19

Entrant Name Ronstan Tensile Architecture

Address 19 Park Way, Braeside, VIC, 3185

Contact Phone Number 03 8586 2000

Email Address

Website Address www.ronstantensilearch.com

Entrant Type / Role Other; Specialist Building Subcontractor Design and Construct

Project Client Flinders University

Project Architect Cox Architecture

Structural Engineer Mott McDonald

Specialist Consultant & Role Tensys Eng

Building Contractor Built

Others X-Tend Mesh -Carl Stahl

Steelwork - Gant & Sons

Fabric - Hardco