The type of structures built for the recent London Olympics were radically different from those of the earlier Sydney Olympics. The facilities for both events were intended to be constructed in an "environmentally friendly manner". The Sydney structures essentially banned the use of fabrics whereas in London it was embraced.

Many of the London structures could be resized, relocated and reused - critical aspects of the conference theme "Touching the Earth Lightly".

The presentation will be given by Farid Sahnoune of Ferrari.

The presentation will cover the conceptual ideas behind choosing the waka as the perfect venue for this project including the Maori protocols with choosing such a design.

Design Brief

- Major Event focus

- Visitor focus

- Construction and Deconstruction requirements

- Ease of storage

- Ease of Transport

- Future use for events

- Design expertise that were met by Structurflex and Compusoft

Expectations

- The tribe

- The funding organisations

The reality and actual experience

- Rugby World Cup

- Economic, Cultural and Social outputs

- TeamNZ

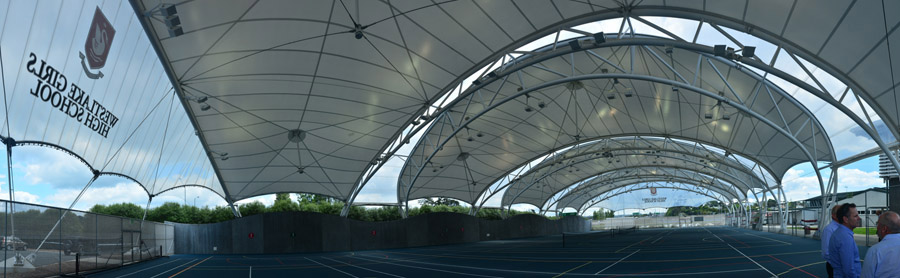

In 2011 Creative Spaces was commissioned to design a cover for proposed new netball courts at Westlake Girls High School in Auckland. This presentation will cover the design of the project from initial concept to the completion of construction.

The presentation will be given by Harry Street.

Harry Street is Design Director and a founding partner of Creative Spaces Limited, a fellow of the NZIA and immediate past Chairman of the NZIA Auckland Branch. In a career spanning nearly forty years and a number of countries Harry has worked on the design of a number of different building types, including sports and recreation projects, and has been involved with projects such as North Harbour Stadium, Tamaki College Community Recreation Centre, Taupo Events Centre, Dilworth Sports Centre, Burnham Gymnasium, Vodafone Events Centre (formerly TelstraClear Pacific Events Centre)

The Feature ETFE and Timber Diagrid Roof - Coastland Aquatic Centre

The new 2000m2 double curved transparent roof, provides a stunning internal environment for sports and recreation, a presents new possibilities for aquatic centres in New Zealand. It’s the first example of ETFE being used on an Aquatic Centre in Australasia, and is attracting a lot of attention in the aquatic industry.

The design of the vaulting diagrid form, drew on a wide variety of specialist design skills to ensure a holistic approach to the design of the main pool hall.

The Architectural Design of Bridges

Digital models are explicit - every aspect of a design is well-defined and can be described. A digital model in which a design is represented explicitly allows us, for example, to get the coordinates of any point, to produce plans, sections and elevations and eventually, to build.

Parametric models are different. A parametric model depends upon relationships between parts. A parametric model is defined by rules and constraints, which define aspects of a design and their relationships with each other. Changing a rule or constraint, or modifying a part of the model itself, has implications on the entire model.

Warren and Mahoney employ two pieces of parametric software – Bentley’s Generative Components and McNeel’s Rhinoceros with Grasshopper and have recently won several infrastructure design projects.

The lecture will focus on the use of parametric modelling, using Rhinoceros and Grasshopper - in the design of three key projects. It will discuss Hendon Bridge - a 320 metre long pedestrian footbridge over the new State Highway 20 extension at Waterview; Memorial Bridge, Christchurch - a gateway bridge to Christchurch and Pt Resolution bridge, an 80 metre long pedestrian bridge connecting Tamaki Drive with the Pt Resolution headland and Parnell baths.

Singapore’s National Stadium roof is the centrepiece of the Singapore Sports Hub. Once completed in 2014 this highly efficient structure will be the largest free spanning dome in the world with a clear span of 310m and a rise of 73m from the concourse level. The fixed roof dome supports a symmetrical movable roof that is in two halves and giant PTFE louvres. The thrust of the dome is supported by a post-tensioned ring beam.

The architecture of the cladding was clearly developed to express the design and geometry of the structure. To achieve a steel weight of 110kg/m2 over the footprint area of the dome required this cladding to be lightweight. A multi-layer ETFE pillow system was chosen for the cladding of the movable roof due to its flexibility, environmental performance and the ability to illuminate it at night. The giant hung PTFE Louvres provide a naturally ventilated concourse. The Louvre steel structure has been released in such a way that it does not try to support the thrust of the dome.

The presentation will be given by Scott Rathie of Arups.

The ‘piece de resistance’ of the recently renovated ISPT Wintergarden Centre in Queen Street Mall Brisbane is the art façade. The art façade is a 3D depiction of a ‘winter’s garden’ and combines laser cut and bent stainless steel and 16 different poweder coated aluminium fixed over a hidden structural steel grillage. 3D stainless steel composite shapes help depict leaves on trees and butterflies over Edward St and Elizabeth St.

The presentation will be given by James Marr of Tensys Engineers.

Some of the projects / presentations for the LSAA 2013 "Touching the Earth Lightly" Conference.

Peter Lim, LSAA Vice President, from Tensys, will give a presentation about the recently completed Abdullah bin Khalifa Stadium in Doha. It has seating for 12,000 and the tension fabric structure roof provides shading for about 60% of the seating area.

Harry Street, Creative Spaces, ex Philip Cox,will give a presentation on Westlake Girls High School – Sports Facility- refer www.structurflex.com

Westlake Girls High School on Auckland’s North Shore has a reputation for high achievement. With a strategic focus on encouraging personal best, the school wanted to enable increased use of their netball and tennis courts by adding an all-weather canopy. The vision called for full light between each netball court with more shade for on-court players.

Chris Kelly, Architecture Workshop, will also present on Waitomo Caves Visitors Centre- refer www.archwksp.co.nz Sheltered below an innovative woven timber canopy, new amenities for visitors to the Waitomo Caves includes tourist gathering areas, a 250-seat dining, retail, seminar and exhibition areas as well as a café and theatre for Tourism Holdings Ltd.

|

|

|

Facades are becoming an important element to control the internal environment of modern buildings - both enclosed such as offices, and open such as car parking stations.

Many facades are set at a distance from the building envelope and this permits the use of cable supported systems.

A number of case studies will be presented by Rown Murray, General Manager of Ronstan (Silver sponsors)

|

|

Keynote Address: Alex Matovic - Grimshaw Architects (Melbourne)

"Touching the Earth Lightly: A Responsive Architecture."

Abstract:

Architecture in this century has a responsibility. It must respond to a wide range of forces that act upon it, whether that is economic, social, environmental or a purely pragmatic response to a difficult site. It should be of and connected to its time, while being timeless in its craft. Neil will outline an approach to design, citing examples from across the globe such as the Eden Project and Southern Cross Station, that allows the creation of a responsive architecture. One that ultimately can provide great aspiration without relying on an outcome driven by stylistic sensibilities.

The Cloud is a temporary lightweight structure provided by the New Zealand government as an inner-city Fanzone, festival and showcase venue during the 2011 Rugby World Cup hosted by New Zealand.

The venue is ideally located on the western edge of Queens Wharf and was a very popular place for fans to watch the games during the event. The development of the site at Queens Wharf, demolition of an old structure and building of a new venue was a controversial issue at the time and presented a number of engineering challenges. The structure is a development of an earlier project “The Telecom Shed” built in the same area as a sponsors display venue for the 2003 Americas Cup. Architectural design was by Jasmax. At 180m long x 30m wide steel framed building can accommodate 5000 people and is clad in a combination of Ferrari PVC, ETFE and glass. The Cloud was built by Fabric Structure Systems and engineered by Wade Design Engineers.

The presentation will be given by Joseph Dean, Managing Director of Wade Design Engineers.

The Cloud is one of three projects included on the Friday Afternoon's Site Visits.

Innovating the Process - Adelaide Oval Roof Structures

Parametric Design, Optimisation, Fabrication

The ability of a parametric system to handle inter-object dependencies opens innovative ways for a design team to explore a large number of design iterations within a compressed timeframe. This advanced design technology offers new ways for close collaboration in the development of lightweight structures involving architects, engineers and fabricators.

This progressive design process has been implemented on a number of projects including the $500 million redevelopment of the Adelaide Oval. The 145m wide spanning south roof diagrid shell and the five diagrid shells with varying spans of up to 50m of the east roof are clad with a PTFE fabric.

Joachim Claus from Cox Architecture will present on the key steps of this innovative and collaborative process on the Adelaide Oval and other projects.

Sheltered below an innovative woven timber gridshell canopy, new amenities for visitors to the Waitomo Caves includes tourist gathering areas, 250-seat dining, retail, seminar and exhibition areas as well as a café and theatre.

A gridshell is a hybrid of two structural types. A structural grid that follows a two directional curving surface with sufficient grid elements that it acts structurally like a shell. The canopy gridshell is cut from the surface of a toroid, in this case a donut. Whilst the ribs are generated from this toroid, the form is much more complex. This process required extensive structural form-finding, which was done by a mathematical process, a structural modelling process and by back-checking in the 3D CAD geometry.

The cladding comprises of ETFE pillows: cushions of high-strength plastic inflated to 200pa. These cushions could be patterned to the two-directional curvature of the gridshell.

The presentation will be given by Chris Kelly Principal of Architecture Workshop.

Abdullah bin Khalifa Stadium has just been completed by Al Khayyat Construction & Development. It is the new home of the top Qatar league team - Lekhwiya Sports Club and the 1st tensile fabric grandstand stadium roof in Qatar.

The complex creates a 12,000 seat stadium that is rectangular in plan.

Tension fabric structures are used to create shading over 60% of the grand stand seating arena.

The presentation will be given by Peter Lim of Tensys Engineers.

Site Visits to "The Cloud", "Westlake Girls High School" and "Eden Park"

A valuable aspect of LSAA Conferences is to include site visits to recent projects in the company of technical people that were intimately involved with the design, fabrication or erection. In several cases we have organized the current client/owner to be present as well to comment on the performance of the project.

"Westlake Girls Sports Facility"

See also the following article about Westlake Girls - as it received a High Commendation in the 2013 LSAA Design Awards.

|

|

|

|

Site Visits to "The Cloud", "Westlake Girls High School" and "Eden Park"

A valuable aspect of LSAA Conferences is to include site visits to recent projects in the company of technical people that were intimately involved with the design, fabrication or erection. In several cases we have organized the current client/owner to be present as well to comment on the performance of the project.

"The Cloud"

See also the following article about The Cloud - as it was entered into a previous LSAA Design Awards.

Of particular interest to the LSAA Conference delegates concerning the Eden Park Stadium was the use of PTFE foil pillows to clad the rear sections of the stands.

Eden Park has four distinct stands with the newest being the most imposing in terms of capacity, height and visual bulk. The use of the transparent foil panels was partialy selected to lessen this impact as the stadium is located in a residential area.

|

|

|

|

Page 2 of 2