This project was entered in the LSAA 2016 Design Awards (Cat 2 Medium Structures, 2047)

Entrant: Fabric Structure Systems (Designer / Fabricator / Installer)

Location: Whangarei, New Zealand. Completed: April 2016

Client: Whangarei District Council

Team: Wade Design Engineers Ltd, Fabric Structure Systems, Culum Engineering (Steel)

Application

To enhance the CBD environment and aid in the rejuvenation of the central business district to encourage the return of pedestrian traffic therefore enhancing the shopping experience.

Description

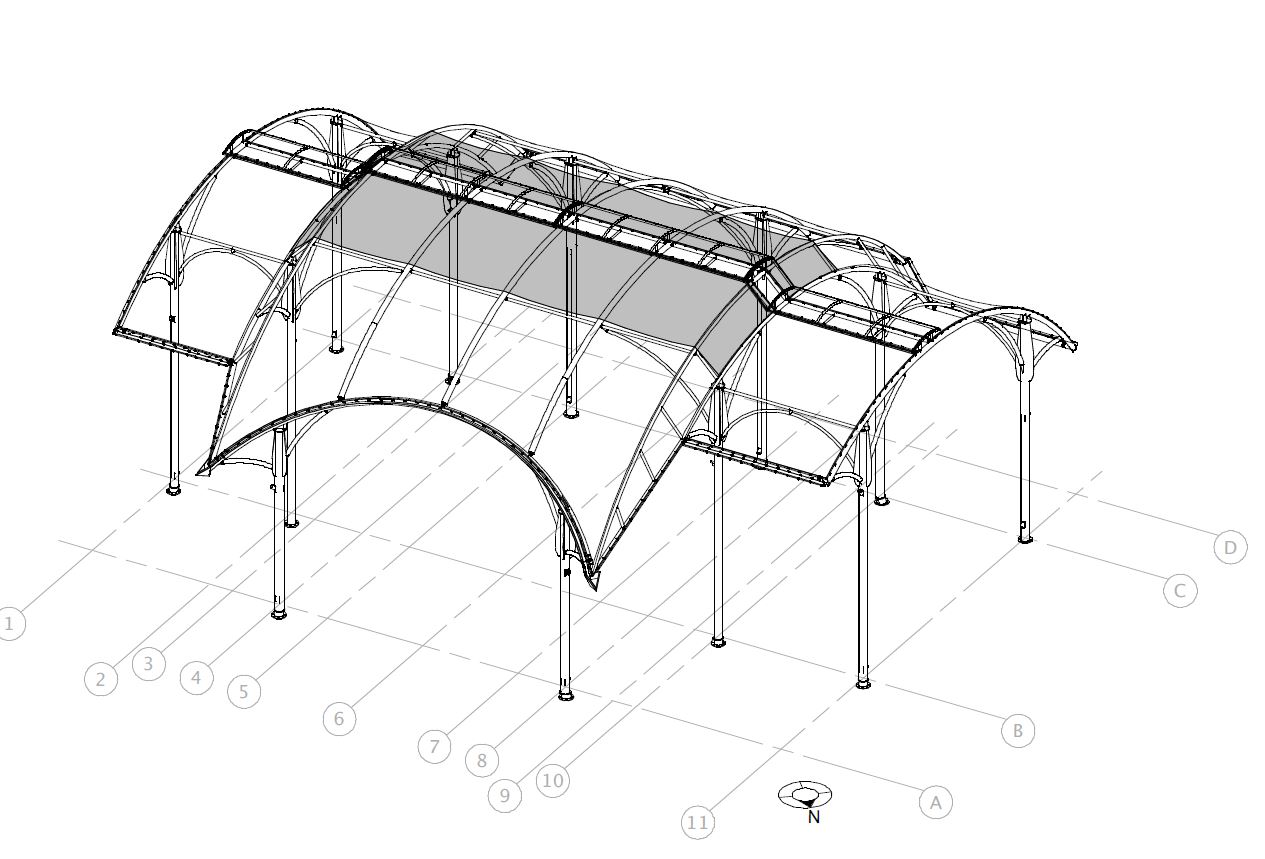

A local council initiative to revitalise the existing town center mall. The new canopy to be an integral feature of the ‘ shared space’ pedestrianizing of the dated 40 year old mall.

The fully grown Melia tree to be accommodated within the canopy roof and its longevity within the new Mall environment guaranteed. ETFE was ruled out as to expensive although being the ideal textile for purpose. The use of Ferrari FX 901 achieved the UV and light required for healthy growth, this combined with Ferrari 782 PVC met the budget .

The foundation engineering and installation of the 8mtr deep piles proved to be extremely complex due undocumented underground services and the need to work alongside the civil contractor (road) who was under a separate contract to council.

The combining of glass fibre FX 901 with architectural grade PVC had not been done prior to this project. The technique for doing so was developed by the fabricator in conjunction with approved testing by the engineer.

The fabricator was responsible for concept, full design and delivery on a fixed budget.

Design Brief

Give an outline and your overall response to the design brief or instructions from the client etc. on which the design / fabrication / installation was based:

The fully grown Melia tree to be accommodated within the canopy roof and its longevity within the new Mall environment guaranteed. ETFE was ruled out as to expensive although being the ideal textile for purpose. The use of Ferrari FX 901 achieved the UV and light required for healthy growth, this combined with Ferrari 782 PVC met the budget .

The foundation engineering and installation of the 8mtr deep piles proved to be extremely complex due undocumented underground services and the need to work alongside the civil contractor (road) who was under a separate contract to council.

The combining of glass fibre FX 901 with architectural grade PVC had not been done prior to this project. The technique for doing so was developed by the fabricator in conjunction with approved testing by the engineer.

The fabricator was responsible for concept, full design and delivery on a fixed budget.

Additional Steel Fins to the steel columns - to represent ‘branches’ off the columns to match the existing tree.

Materials and Fabrication

Serge Ferrari - 782 S2 - Standard PVC with a 15 year warranty in NZ.

Serge Ferrari - FX 901 - To provide additional light to the existing tree beneath the canopy.

Hot air welders used on the 782 S2.

High Frequency welders used on the FX901.

Collaboration

Significant collaboration was required between existing underground services (data cables, sewage, stormwater

pipes, power etc), local council requirements, the clients designated project manager and Fabric Structure

Systems.

Tools used to achieve the positive outcome included:

- a 3D scan of the surrounding buildings before the project and 3D model had started. · Local surveying was required to validate foundation bolt clusters etc.

- The 3D design enabled both steel and fabric to be constructed at the same time, enabling an efficient

installation.

Planned maintenance will be conducted in conjunction with the annual clean as specified.

{Ref: sliders/DA2016/Cat2/2047 DP 110}